Core Values

Kuhn said repairs were necessary because a $5,000 grant from the Oklahoma Historical Society did not include repair to the building. However, the leakage would have adversely affected the blackberry display being constructed inside the north wall through the grant.

“The leakage kept the north wall and floor wet with every blowing rain. It also caused a lot of humidity inside the old block building, which would have been detrimental to the display and to archives being stored in the back area of the building,” Kuhn explained.

A May 3 annual Sunday dinner event had been scheduled to raise funds for the repairs, Kuhn said, but the Covid 19 virus shutdowns prevented that fundraiser. That is where Metal Roofing Contractors stepped in to help so construction of the grant display could continue.

McLoud Historical Society Museum and Heritage Center has been remodeling the former Ford Dealership since 2007 through donations and volunteer labor.

“Thanks to everyone who has donated through memberships, fundraisers, and with lots of labor, to make this beautiful museum available to honor those who have made McLoud the vibrant community of today,” Kuhn said.

The museum will reopen on Fridays as soon as the quarantine allows. For information, please contact the museum through its Facebook Page.

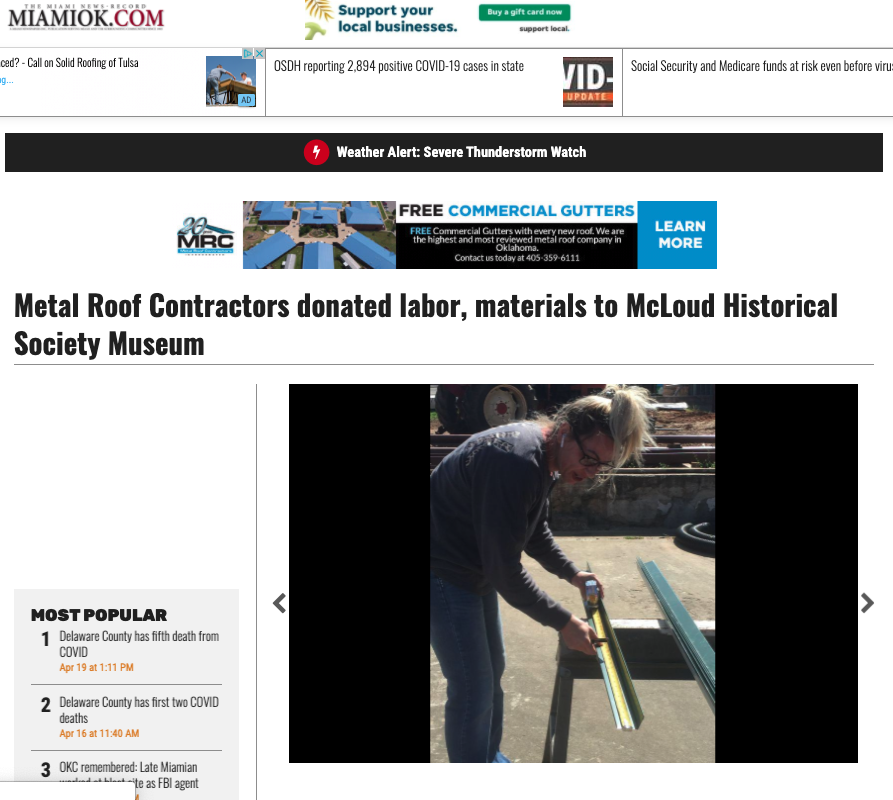

CUT LINE: Megan Ballard cuts metal to be used for repair on the McLoud Historical Society Museum and Heritage Center. CUT LINE: Stephen Kendall uses a lift to repair leakage on the north side of the McLoud Historical Society Museum and Heritage Center on Friday, April 10.

KNOWLEDGE

With more than 50 years of combined industry experience behind them, Metal Roof Contractors gives its clients peace of mind in knowing they have an experienced contractor with high standards delivering quality service. MRC is a professional organization dedicated to getting the job done right the first time.

SUPERIORITY

When our clients choose Metal Roof Contractors, they know they are getting the highest quality materials and installation in addition to superior customer service.

CUSTOMER SATISFACTION

Metal Roof Contractors has a record of excellent customer service. We are proud of the feedback our customers give us, and we are always willing to share it with prospective clients. In fact, with a growing project list of more than 250 completed structures, most of our new-project inquiries come from people who have been referred to us by satisfied customers.

SERVICE

At Metal Roof Contractors, we are dedicated to giving each of our clients the best experience possible. We know businesses cannot stop operating while we complete their projects, so we work hard to deliver top-quality work that is finished on time and with minimal disruption.

How long will it last?

One of the many benefits of metal roofs is longevity. The metal roof panels will last 40-70 years depending on the finish. Finish (Painted and Galvalume) warranties range from 30 to 40 years. Over the 40 to 70 years life span, the panels might encounter aesthetic damages, but as long as the finish is still present (regardless of fade or chalking), the metal panels will perform. With minimal maintenance and reapplying sealants, a standing seam roof system should last 40+ years. In MRC’s over 20 years of experience, none of our projects have been replaced due to panel failure.

What is the difference in metal panel finishes?

Metal Roof Contractors primarily offers 2 types of metal panel finishes. The longest lasting and time proven finish is the industry standard Kynar coating system. The Kynar coating system is warrantied for failures such as fading, chalking, chipping, pealing, etc. Metal Roof Contractors offers many standard 2-coat colors. Metallic colors require an additional coat for the metallic sheen and costs roughly 8-10% more. Any color you can imagine can be formulated, but requires minimum quantities, long lead times and costs to cover paint formulation and interruption. For projects where roof performance is the top priority, a Galavulume finish is the perfect finish. The base material of the metal panel is the same as a painted finished metal panel, but doesn’t require the painting process. This can save up to 20-30% on panel costs. Less expensive and shorter lasting finishes are available for costs savings and are ideal for panel locations not in direct sunlight such as soffits and interior.

What does galavalume look like?

Steel coated with Galvalume appears similar to galvanized steel but with a smoother appearance. Any visible crystals are smaller and closer together than the process of galvanization. Galvalume is applied to both sides of cold-rolled steel sheets using a hot-dip process that protects edges as well. The advantages of galvalume steel: Corrosion resistant, strong, relatively inexpensive (but often slightly more expensive than galvanized).

Do I need underlayment?

The short answer is yes. For architectural metal roof panel systems, a roof underlayment is required to help control water leakage through the roofing system during heavy rain storms or under snow melting conditions. Upgraded roof underlayment is often specified in cold climates for additional protection against ice dam leakage, while high temperature underlayments are designed for use in high temperature environments where the in-service temperature can reach temperatures as high as 240ºF.